Wycinarki laserowe wykorzystują nowoczesną technologię, by w bardzo krótkim czasie i przy stosunkowo niewielkim zużyciu energii tworzyć precyzyjne cięcia – a mowa o dokładności w zakresie 0,001” przy cienkim materiale!

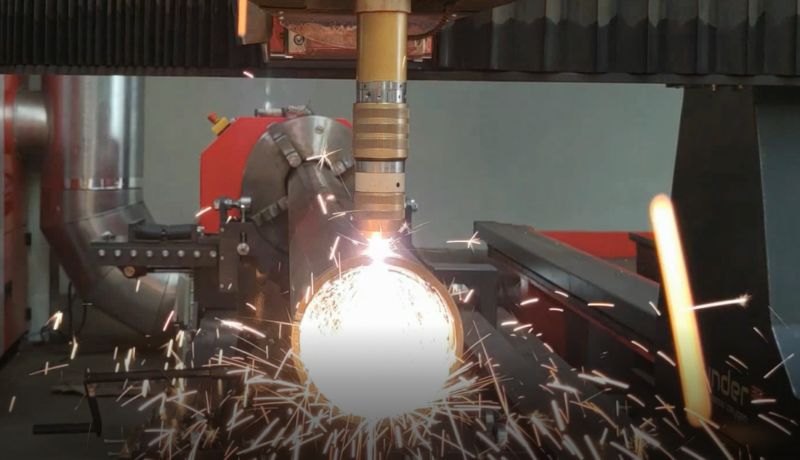

Jedną z najskuteczniejszych metod obróbki aluminium, stali nierdzewnej i innych materiałów przewodzących prąd elektryczny jest cięcie plazmą. Aby znacznie zwiększyć zakres grubości cięcia stali można zastosować w maszynie również cięcie tlenowe.

Waterjety znajdują zastosowanie w wielu gałęziach przemysłu, począwszy od lotniczego, stoczniowego i motoryzacyjnego, przez zdobniczy, kończąc na meblowym czy tekstylnym. Poddana ogromnemu ciśnieniu, woda wraz z dodatkiem materiału ściernego jest w stanie przeciąć nawet kilkudziesięciocentymetrową blachę.

Szeroka oferta wycinarek plazmowych

oraz innych produktów i usług

Rozwiązania dopasowane do Twoich potrzeb

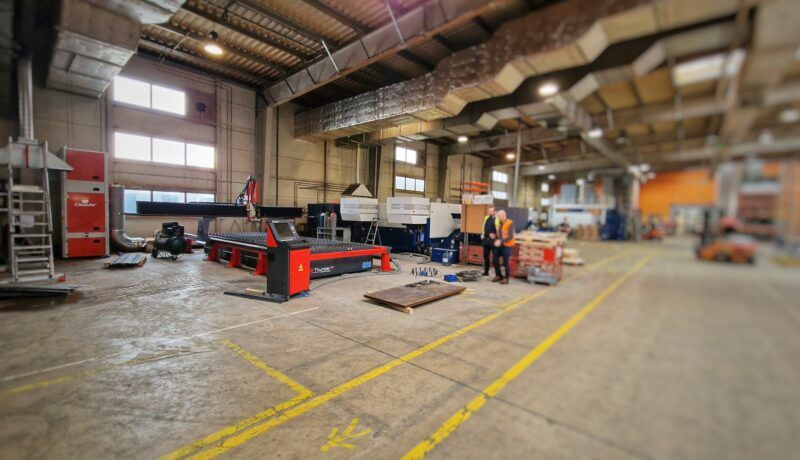

Zdobyte na przestrzeni ostatnich lat doświadczenie pozwala naszemu przedsiębiorstwu na dostarczanie jakościowych urządzeń produkcyjnych. Oferta firmy to nowoczesne maszyny sterowane numerycznie, których rozbudowane funkcje zapewniają doskonałą wydajność pracy. Sprawia to, że prezentowane urządzenia mogą stanowić wyposażenie nie tylko małych zakładów, ale również bardzo dużych przedsiębiorstw przemysłowych. Oferowane maszyny CNC odznaczają się niezwykle prostą i intuicyjną obsługą, dzięki czemu mogą być sprawnie obsługiwane nawet przez niedoświadczonych pracowników.

Postaw na automatyzację procesów!

Robotyzacja przedsiębiorstw jest nieunikniona i dotyka coraz więcej branż. Chcąc podążać za trendami oraz oferować możliwie najwyższej jakości komponenty konieczne jest delegowanie części zadań robotom, które odznaczają się niezwykle szybką oraz dokładną pracą. W ofercie firmy znaleźć można również między innymi wycinarki laserowe, wycinarki plazmowe, plotery CNC czy też aplikatory kleju na gorąco. Wszystkie dostarczane urządzenia pozwalają w znakomity sposób zadbać o wzrost jakości oferowanych produktów, a także o wydajność pracy produkcyjnej. Zapraszamy do obejrzenia wszystkich maszyn dostępnych w ofercie firmy.

01 Gwarancja niezawodności

Dzięki wieloletniemu doświadczeniu i stałemu rozwojowi naszych maszyn, uzyskaliśmy niemal niezawodne urządzenia. Usterki pojawiają się bardzo rzadko, a ich 99% rozwiązujemy w ciągu 24h.

02 Różne formy finansowania

W swojej ofercie posiadamy różne formy finansowania urządzeń dopasowane do Twoich możliwości finansowych, w tym leasing fabryczny, który ułatwia i przyspiesza procesowanie Twojej sprawy.

03 Doświadczona kadra inżynierów

Wychodząc naprzeciw potrzebom rynku, postawiliśmy na stały rozwój naszej kadry inżynierów, dzięki czemu jesteśmy w stanie zrealizować nawet najbardziej złożone projekty, skrojone na miarę indywidualnych potrzeb klienta.

04 Szeroka gama produktów

W ofercie posiadamy urządzenia do kształtowego cięcia dowolnych materiałów, a nasza doświadczony dział sprzedaży odpowiednie dobierze i skonfiguruje maszynę do Twoich potrzeb.

Kompletne linie produkcyjne

Nasza firma działa w Polsce już od wielu lat i zajmuje się dostarczaniem nowoczesnych maszyn sterowanych numerycznie. Oferowane urządzenia są wykonane z niezwykle wytrzymałych materiałów, dzięki czemu mogą być użytkowane przez bardzo długi czas bez konieczności podejmowania jakichkolwiek czynności serwisowych oraz naprawczych. Prezentowane linie produkcyjne dzięki swojej wysokiej wydajności pracy mogą być montowane nie tylko w małych zakładach, ale również w dużych przedsiębiorstwach przemysłowych.

Szeroka oferta firmy

W ramach prowadzonych działań oferujemy jakościowe urządzenia wspomagające różnego rodzaju procesy produkcyjne. Propozycja firmy to między innymi wycinarki laserowe, wypalarki plazmowe, plotery CNC, a także aplikatory kleju na gorąco. Dostarczane maszyny pozwalają na przeprowadzanie w pełni zautomatyzowanej produkcji w taki sposób, aby możliwe było wyeliminowanie wszelkich błędów podczas procesu. Zachęcamy do zapoznania się z całością oferty naszej firmy oraz do wybrania najodpowiedniejszych maszyn dla swoich potrzeb.

Zapraszamy na Międzynarodowe Targi Branżowe

- Tech Industry 2023 Ryga

Kipsala Exhibition Centre, Ryga, Łotwa: 30.11-02.12.2024 - Targi Obróbki Metali, Obrabiarek i Narzędzi STOM-TOOL

Targi Kielce: 19-22.03.2024

Numer stoiska: D31